Your basket is currently empty!

Anymal Digital Hatchery

Genetically Improved Catfish for Sustainable Aquaculture

Anymal Anytime supports a state-of-the-art African catfish hatchery capable of producing 1,000,000 juveniles annually. This scalable, sustainable hatchery model integrates advanced aquaculture systems and efficient design principles to optimize production and ensure reliability.

The system includes:

Components:

- 2x African Catfish Broodstock Systems: Each with filtration systems (sedimentation and biological), adjustable SS304 frames, and UV-C sterilizers.

- 1x African Catfish Isolation System: For isolating fish with dedicated tanks and filtration.

- 2x African Catfish Hatching Systems: Includes egg trays, sedimentation filters, and aeration.

- 9x African Catfish Fingerling Systems: Supports 15 cycles per year with a production capacity of 12,600 fish per cycle (1 gram final size).

- 9x African Catfish Juvenile Systems: Supports 12 cycles per year with a production capacity of 10,000 fish per cycle (5 gram final size).

- 1x Artemia Hatching System (Large): Produces 1,080 grams of Artemia cysts per cycle, essential for first feed.

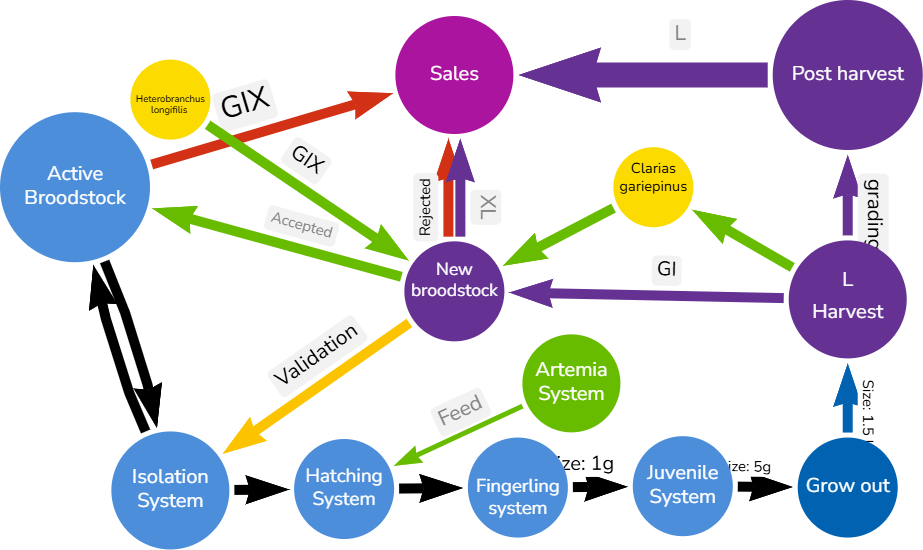

Process Flow

- Active Broodstock:

- Fish from the active broodstock system are moved to the isolation system for mating.

- Egg Production:

- Eggs produced are transferred to the hatching system for incubation and hatching.

- Fingerling System:

- Hatched fry are moved to the fingerling system to grow until they reach a size of 1 gram.

- Juvenile System:

- Fingerlings are transferred to the juvenile system to grow to 5 grams.

- Grow-Out Process:

- At 5 grams, juveniles are moved to grow-out systems for further growth.

- Fish are grown to a size of 1.5 kg, at which point they are harvested and graded.

- Grading and Selection:

- Top-notch specimens are moved to the Genetically Improved (GI) program called New Broodstock.

- Fish for live deliveries are also graded and prepared.

- Genetically Improved Exchange (GIX):

- Heterobranchus sp. are acquired for testing.

- If the test batch is successful, fish are moved to the active broodstock system.

- Selling Active Broodstock:

- Active broodstock are sold to other facilities participating in the GIX program to prevent inbreeding and ensure genetic diversity.

Operational Requirements:

Operational Expenses (OPEX):

| Expense Type | Description | Annual Cost (USD) |

|---|---|---|

| Electricity | Daily consumption of approx. 8.25 kWh at $0.30/kWh | $902 |

| Water | Daily consumption of approx. 8 m³ at $1/m³ | $2,880 |

| Labor | Manager ($1,000/month), 2 Technicians ($600/month each), Support Staff ($400/month) | $31,200 |

| Feed and Artemia Cysts | Includes Artemia cysts ($1,800/year) and feed ($1,500/year) | $3,300 |

| Broodstock Costs | Heterobranchus broodstock maintenance | $5,000 |

| Maintenance | Regular system maintenance | $1,000 |

| Other Costs | Transport, utilities, and testing | $2,000 |

| Total OPEX | Sum of all operational expenses | $46,282 |

| Depreciation | Annualized CAPEX depreciation over 10 years | $15,000 |

| Total Cost | Total OPEX + Depreciation | $61,282 |

| Cost Per Fingerling | Based on 1,000,000 juveniles/year | $0.061 |

Electricity

- Daily Energy Consumption: Approx. 8.25 kWh/day. Price 0.3 USD per kwh at 900 USD/ year

Water

- Daily Water Consumption: Approx. 8 m³/day.

- Annual Cost: $2,880/year (assuming $1/m³).

Labor

- Hatchery Manager: 1 person, $1,000/month.

- Technicians: 2 people, $600/month each.

- Support Staff: 1 person, $400/month.

- Annual Labor Cost: $31,200/year.

Feed, Artemia Cysts, and Broodstock Costs

- Artemia Cysts: $1,800/year.

- Heterobranchus Broodstock: Estimated cost for acquiring and maintaining new broodstock: $5,000/year.

- Clarias Broodstock: The GIX program ensures a balanced exchange, with the same number of broodstock sold as added, resulting in no additional net cost.

- Fingerling and Juvenile Feed: $1,500/year.

Maintenance

- Annual Maintenance Cost: $1,000/year.

Other Costs

- Miscellaneous (transport, utilities, testing): $2,000/year.

Cost Analysis

- Reliability Margin: The hatchery employs a reliability margin to ensure sufficient fingerlings for all operations. Each cluster requires 6 double culls and 12 double splits per harvest. There are 3 harvests per year. This leads to an annual fingerling demand of 864,000. With a total production capacity of 1,080,000 fingerlings per year, this results in a reliability margin of (1,080,000 – 864,000) / 1,080,000 = 20%, ensuring operational stability.

- Excess Fingerlings: With a reliability margin of 20%, there is likely a demand to sell the excess fingerlings. The estimated price for 5-gram fingerlings is 15 KSh (~USD 0.10), creating an additional revenue stream. Approximate total revenue from selling excess fingerlings is estimated at USD 20,000 annually.

Operational Requirements:

- First Transport: Two 40ft HC containers.

- Water Consumption: Approx. 8 m³/day.

- Energy Consumption: Approx. 8.25 kWh/day.

- Surface Area: Approx. 500 m².

Summary

- CAPEX: $150,000 (depreciated over 10 years).

- OPEX: $46,282/year.

- Total Annual Costs: $61,282/year.

- Cost Per Juvenile: $0.062 (based on 1,000,000 juveniles/year).

This cost structure highlights the efficiency and scalability of the hatchery model, ensuring sustainable operations and competitive production costs. The cycle for juveniles delivers 12 batches per year. This is synchronized with 3 harvests every 4 months in 18 grow-out tanks.

The main production focus is on Heteroclarias and male Clarias for market purposes. Female Clarias are primarily reserved for breeding.

This model is designed to maximize efficiency, ensure reliable juvenile production, and provide scalable solutions for aquaculture.

Appendix: Ingoing System Components

Broodstock System

- 2x Polypropylene fish tanks with two outlets; one for return to sedimentation tank and one for draining the tank completely.

- 2x Covers (SS304) to prevent fish from jumping out.

- Sedimentation filter tank for mechanical filtration.

- Moving bed filter tanks for biological filtration (ammonia to nitrate conversion).

- Pump tank with freshwater supply and overflow pipe.

- Frame (SS304) with adjustable stands.

- 1x Messner pump (70 W – 240 V).

- 1x 40-watt VGE UV-C unit (SS304 housing).

- 1x Air pump (160 W – 240 V).

- Floating valve and ball valve for freshwater supply.

- PVC piping and fittings.

Isolation System

- 2x Polypropylene fish tanks.

- Frame (SS304) with adjustable stands.

- Freshwater supply connections.

- PVC piping and fittings.

Hatching System

- 4x Polypropylene fish tanks with 1 outlet and two types of outflow sieves (large and small).

- Sedimentation filter tank for mechanical filtration.

- Pump tank with freshwater supply and overflow pipe.

- Frame (SS304) with adjustable stands.

- 1x Messner pump (70 W – 240 V).

- 1x 40-watt VGE UV-C unit (SS304 housing).

- 1x Air pump (50 W – 240 V) with supply line and air diffusers.

- 4x Floating egg trays.

- PVC piping and fittings.

Fingerling System

- 2x Polypropylene fish tanks with two outlets.

- Sedimentation filter tank for mechanical filtration.

- Moving bed filter tanks for biological filtration.

- Pump tank with freshwater supply and overflow pipe.

- Frame (SS304) with adjustable stands.

- 1x Messner pump (70 W – 240 V).

- 1x 40-watt VGE UV-C unit (SS304 housing).

- 1x Air pump (160 W – 240 V).

- Floating valve and ball valve for freshwater supply.

- PVC piping and fittings.

Juvenile System

- 2x Polypropylene fish tanks with two outlets.

- Sedimentation filter tank for mechanical filtration.

- Moving bed filter tanks for biological filtration.

- Pump tank with freshwater supply and overflow pipe.

- Frame (SS304) with adjustable stands.

- 1x Messner pump (70 W – 240 V).

- 1x 40-watt VGE UV-C unit (SS304 housing).

- 1x Air pump (160 W – 240 V).

- Floating valve and ball valve for freshwater supply.

- PVC piping and fittings.

Artemia Hatching System (Large)

- 4x Polyethylene funnels (113 liters) with bottom outlet and ball valve.

- Frame (SS304) with adjustable stands.

- 2x TL-pendant 2x 36 Watt (240 V).

- Air pump (72 W – 240 V) with supply line and air diffusers.

- Central gutter outlet and Artemia harvest sieve.

- PVC plate with aeration line.

Build the future of aquaculture with this optimized hatchery model!

Leave a Reply